The Power to Imagine series - The ability to increase the surface energy of dificult surfaces so you can bond to them!

In the medical device manufacturing industry, a wide range of materials are used, these materials have many useful properties, which make them the materials of choice for certain projects namely high chemical resistance, temperature resistance and flexibility.

These very properties that make them so useful in the finished product create severe limitations when trying to achieve high bond strengths for adhesives and inks when bonding to them.

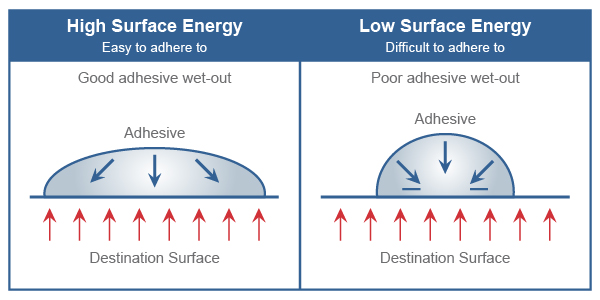

Many of these materials namely Polypropylene, Polyethylene, Nylon 12 and other Polyolefins have low surface energy which prevent adhesives and inks from wetting out the surface properly and limits the bond strength onto these surfaces

Bond strength between adhesives and substrates relies on one specific property: surface energy or tension. Surface tension is measured in dyne/cm (mili N/m) and is the deciding factor on how well a liquid adheres to a surface.

For a proper bond to exist between a liquid and a surface, the substrate’s surface tension must exceed the liquid’s surface tension energy by 2-10 dyne/cm. The higher the surface tension of the substrate in relation to the liquid, the better its ‘wettability’.

Typical substrates

Surface energy (dynes)

PTFE 18

Silicone 21

Polyethylene 31

PVC 40

Polyamide 6/6 46

Water 72

Adhesives 30-47

To test the surface energy of your substrates the quickest and easiest way is to use Dyne Pens.

We offer the industry leading range of medical grade adhesives from Panacol adhesives plasbut even these adhesives need a little helping hand when bonding to some dififcult surfaces.

For a selector guide for our full range of medical grade adhesives please click here

To help get the best results when bonding to these surfaces we offer a range of Corona and Plasma treatment systems from 3DT to help you get the very best bonds.

For full details on how Corona and Plasma treatment systems work please click here

.jpg)

Dyne test results on medical tubing before and after Corona treatment.

We are more than happy to demonstrate these products and show how we can help you get the best results from your bonding process.

Just reply to this email and we can can discuss how ECT adhesives can help you.

ECT Adhesives- The Power to Imagine a better manufacturing future.