Dispense Valves

Dispense Valves

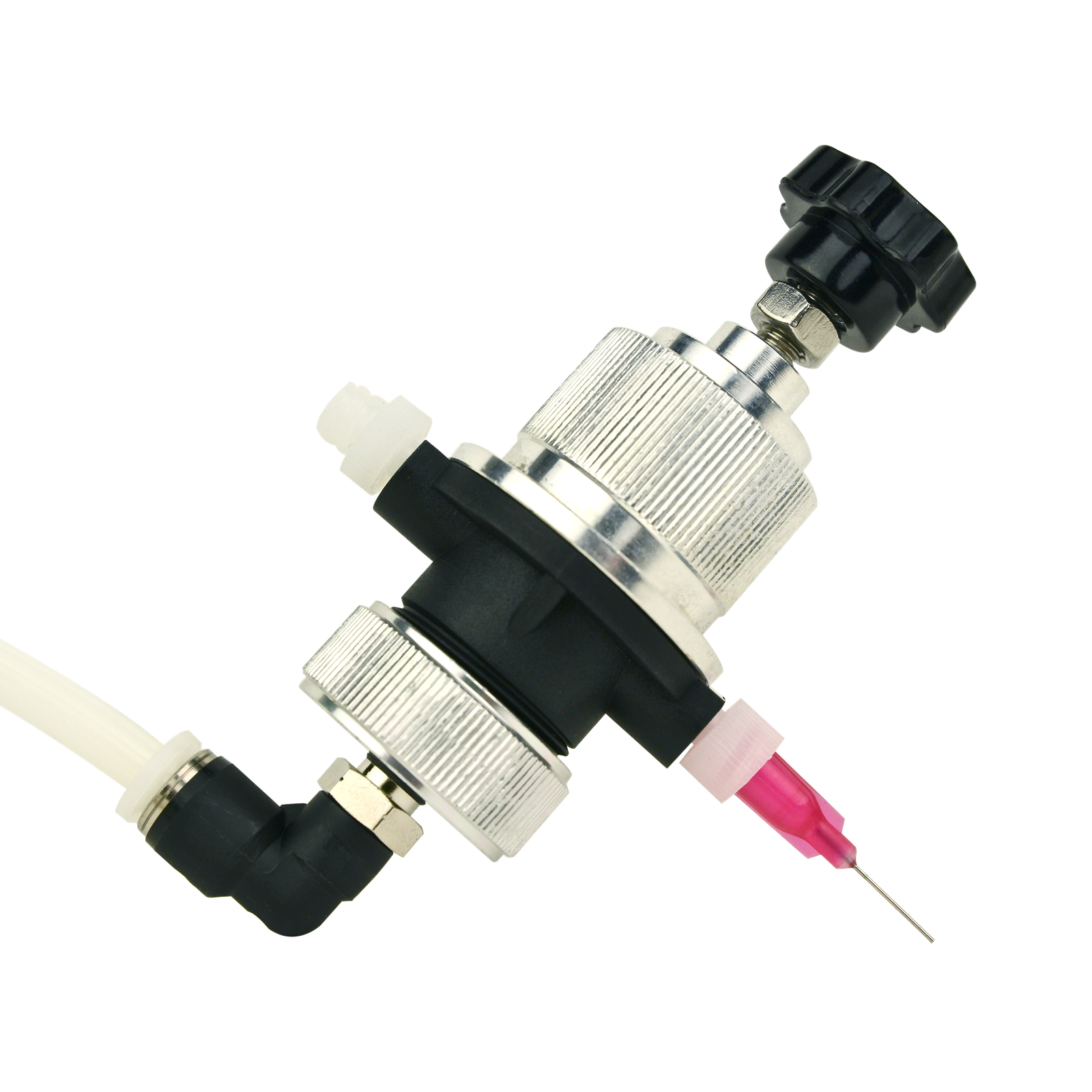

We offer a wide range of dispense valves to help you dispense the correct amount every time. Determining the correct valve for an application depends on a number of factors, including the chemistry of the material to be dispensed, the viscosity of the material, the final dispense amount required and the frequency of dispense shots.

We work with our customers to find the best dispense valve for each application. These valves can then be sold as part of a stand alone dispensing solution, incorporated into a machine that our customer is building or placed on one of our Fisnar Dispense robots.

We offer spool valves for high viscosity materials, poppet valves for smaller shots sizes, diaphragm valves for volatile fluids and UV resins, pinch-tube valves for volatiles and cyanoacrylates, needle valves for dots, and auger valves are for high viscosity fluids such as solder paste applications.

Our Dispense Valves Range

Progressive cavity valve which offers true volumetric dispensing.

Progressive cavity valve which offers true volumetric dispensing of two part materials.

Progressive cavity valve which offers true volumetric dispensing.

Spray valve provides close tolerance spraying of fluids of up to 1000cps.

No-clog spray valve for low-viscosity materials,

Pinch Tube Dispensing Valve ideal for 2-part epoxies and cyanoacrylates

Diaphragm valve designed for precise flow control of low to medium viscosity materials.

Micro Shot Dispensing Valves designed for precision dispensing