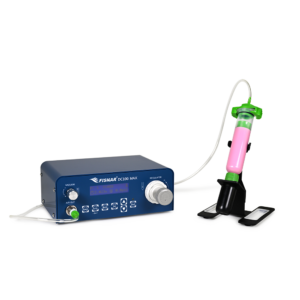

The DA35 extrudes medium to high viscosity materials under pressure directly from a pre-filled can. This system is suitable for automatic and semiautomatic controlled dispensing applications, which require a constant supply of air-free material.

The extruder pump body is fitted with a follower plate that seals and follows the material as the level drops to wipe the sides of the can clean, limiting waste. Supplied as standard with a NBR wiper seal fitted. Hose, valve, handle, and FKM wiper seal sold separately.

Key Features

- Prevents air bubbles and material voids

- Air ram assist to help drive material

- Simple load mechanism provides easy cleaning

- Easy hook up for automatic systems

- Low-noise electric extruder model

- Integrated low-level alarm and warning light

Models

DA35-1KG-US: Autocan Pump 110 VAC

DA35-3KG-US: Autocan Pump 110 VAC

DA35-1KG-EU: Autocan Pump 220 VAC

DA35-3KG-EU: Autocan Pump 220 VAC

DA35-1KG-UK: Autocan Pump 220 VAC

DA35-3KG-UK: Autocan Pump 220 VAC

Specifications

Size 215 x 440 mm (8.46 x 17.32”)

Height Adjustment 550 mm min – 720 mm max (21.65” min – 28.35” max)

Power Input for Sensing 110 – 220 VAC, 50 – 60 Hz

Air Input Pressure 30 – 100 psi

Maximum Output Pressure 850 psi

Fluid Viscosity Range 30,000 – 300,000 cps

Ratio 8.5

Volume/Stroke 5 cc

Max Pump Speed 60rpm

Air Inlet/Fluid Outlet Size 1/4” NPT (f)

Wetted Parts PTFE, Viton®, and PEEK seals

Weight 12.73 kg (28 lb)

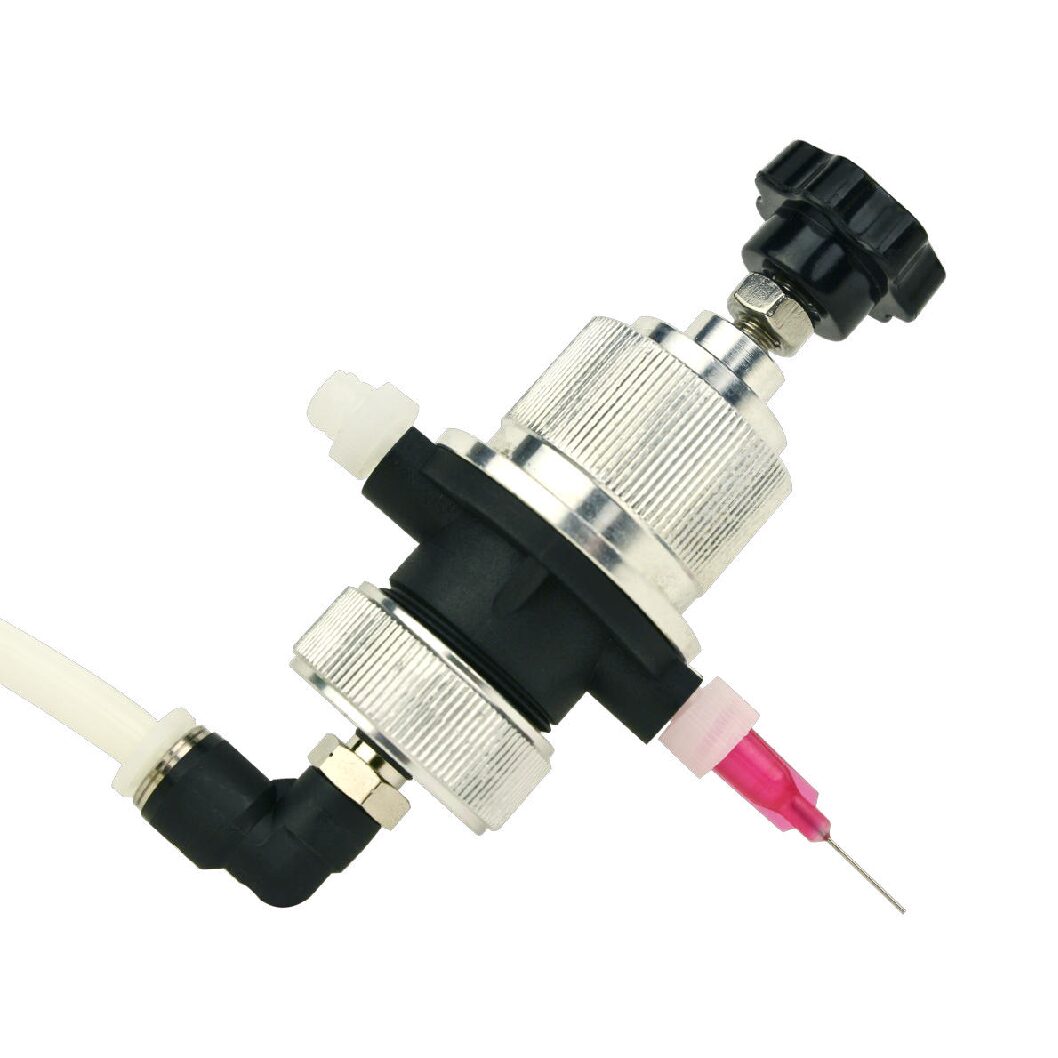

Accessories

651780-A3A-B Fluid Regulator SS 3,000 psi

EP1415K Fluid Regulator Install Kit with Gauge Fittings

DA35-1KG Follower Plate 1 kg

DA35-3KG Follower Plate 3 kg

1300060-1KG-NBR Follower Wiper Seal NBR (117 mm O.D.)

1300060-3KG-NBR Follower Wiper Seal NBR (168 mm O.D.)

1300060-1KG-FKM Follower Wiper Seal FKM (117 mm O.D.)

1300060-3KG-FKM Follower Wiper Seal FKM (168 mm O.D.)

Reviews

There are no reviews yet.